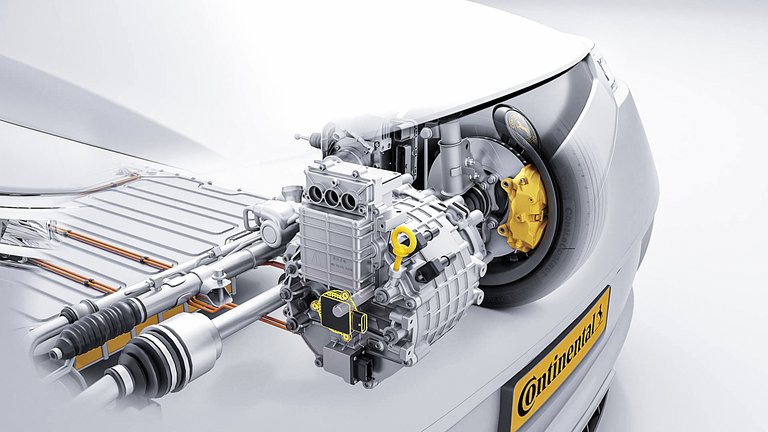

Continental’s New E-Motor Rotor Position Sensor: More Efficiency and Smoother Operations for Electric Vehicles

- Motor management with utmost effectivity: high-speed Rotor Place Sensor makes use of inductive know-how to detect the rotor place in a synchronous electrical machine

- Benefits over present sensors of the resolver sort are: It’s extremely environment friendly, light-weight, extra compact and standardized to be used throughout a variety of motors

- Continental strives to develop into one of many main electrical motor place sensor suppliers along with its robust place in engine place sensors

Toulouse, France, February 22, 2023. Expertise firm Continental is increasing its sensor portfolio for the fast-growing electrical automotive market with the revealing of a brand new modern sensor. The high-speed inductive e-motor Rotor Place Sensor (eRPS) detects the precise place of the rotor in a synchronous electrical machine, which helps to extend effectivity and permits smoother operations. In comparison with present resolver sensors, the eRPS is extra compact and 40 p.c lighter in weight. Current options for rotation measurement are sometimes based mostly on the resolver precept (a rotary electrical transformer), which is difficult and must be tailored to every sort of synchronous motors particularly. The eRPS, nevertheless, is a standardized part for each motor whatever the variety of pole pairs. It’s simple to hold over this new sensor from one motor to a different, making it a gorgeous possibility for electrical automobiles. The beginning of manufacturing is deliberate for the top of 2025.

“The expansion in automobile electrification interprets into extra synchronous motors within the automotive. This ranges from large and highly effective ones like traction motors to smaller ones like electrical pumps. Our standardized eRPS know-how has a variety of potential purposes in electrical automobiles,” mentioned Laurent Fabre, head of the Passive Security and Sensorics Section at Continental. “Measurement precision, compact dimensions and the all-in-one sensor idea combining a number of features add to a excessive degree of integration within the automotive. Continental is likely one of the leaders within the provide of engine place sensors at the moment. With the launch of the eRPS, we at the moment are properly positioned to be one of many main suppliers for electrical motor place sensors, too.”

Compactness and precision make the eRPS the perfect alternative for electrical mobility

The eRPS was specifically developed to manage synchronous motors (the place the rotor rotates on the identical velocity because the revolving discipline within the machine). To attain most motor effectivity, the motor management unit must know the precise place of the rotor, which makes the sort of sensor a necessary a part of synchronous motor purposes. Whereas the resolver is a relatively huge sensor, the eRPS could be very flat and helps compact motor designs with a small general size. The sensor design relies on eddy present precept and is optimized to extend robustness to mechanical tolerances. State-of-the-art built-in circuits (ICs) are used for sign processing. The IC has been designed in keeping with ISO 26262 purposeful security automotive requirements to succeed in ASIL C. As an possibility, two ICs could be embedded within the eRPS to make sure the redundancy that’s an integral a part of purposeful security.

Although the traction motor of an electrical or hybrid automobile is a outstanding use case, there are a lot of extra synchronous motors in electrified automobiles. Future dry-brake methods (with out hydraulics), as an example, may also be actuated electrically and would require rotation sensors. When growing the eRPS, Continental took on present data and expertise with inductive know-how. For instance, the brake-by-wire system MK C2 makes use of an Inductive Motor Place Sensor and has been a benchmark for the sensing idea growth with elevated velocity and accuracy, as is the case with the eRPS.

Precision movement detection through inductive know-how

The brand new eRPS is an inductive rotor place sensor protecting a number of integration configurations. The sensor could be mounted by means of the shaft, or it may very well be built-in on the finish of the rotor shaft, together with on this case the sealing operate. The module comprises excitation and reception coils embedding one or two ICs that detects instantly {the electrical} angular place of the metallic encoder on the rotor shaft. This simple and weight environment friendly answer delivers an output in a format that requires minimal sign publish processing. {The electrical} angular place information is required for an environment friendly e-machine torque management and to attain the utmost service lifetime of a motor.

“The sign sample of the eRPS is far simpler to work with than that of a resolver. The measurement precept could be very quick, extraordinarily sturdy and is suited to excessive motor speeds and acceleration. It is rather compact and works with a minimal variety of elements,” mentioned Ronan LeRoy, head of Sensors and Subsystems Product Middle within the Passive Security and Sensorics Section at Continental.

With a most present consumption of 15mA, the eRPS presents {an electrical} accuracy of ±0,5° for a 4 pole pairs motor. It’s designed to cowl rotational velocity necessities wanted for future electrical automobile platforms (~24.000 rpm). The sensor’s working temperature vary could be very extensive and falls inside -40 °C to 140 °C and peaks as much as 155 °C.

Complete portfolio of sensors for the engine and battery of electrical automobiles

The eRPS is extending Continental’s sensor portfolio particularly designed for electromobility to help each, highway security and electrification. With the Present Sensor Module and Battery Affect Detection, the corporate already launched within the yr 2022 two new options specializing in defending the battery and/or on battery retention of electrical automobiles.